Yokota Pneumatic System Wrench

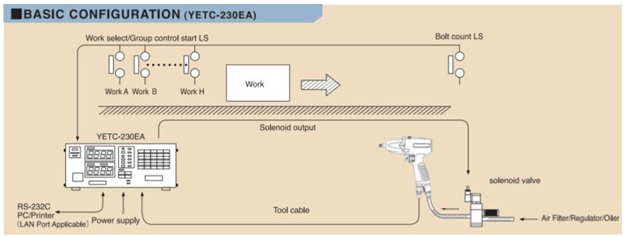

Yokota has developed pneumatic system wrench for the purpose of tightening bolts at a very high speed with accuracy. Yokota pneumatic system wrench has features like: - count bolts in a group, detection of tightening error like under & above tightening, double hit, cross thread, free bolt. Pneumatic system wrench can be integrated with production line control system for quality production & it also has an ability to exchange the tightening data for analyses & traceability purposes Pneumatic system wrench does not only have tools with having a torque transducer on the main shaft but also an angle encoder to monitor tightening angle. By controlling the torque and monitoring the angle, all errors that can occur during the tightening process are detected.

Yokota has developed pneumatic system wrench for the purpose of tightening bolts at a very high speed with accuracy. Yokota pneumatic system wrench has features like: - count bolts in a group, detection of tightening error like under & above tightening, double hit, cross thread, free bolt. Pneumatic system wrench can be integrated with production line control system for quality production & it also has an ability to exchange the tightening data for analyses & traceability purposes Pneumatic system wrench does not only have tools with having a torque transducer on the main shaft but also an angle encoder to monitor tightening angle. By controlling the torque and monitoring the angle, all errors that can occur during the tightening process are detected.

Features of Pneumatic system wrench: -

• Direct torque detection

Torque is directly detected in yokota system wrench by the strain gauge sensor is attached to main shaft for precise tightening data can be obtained.

• Automatic shut-off

The tool can be automatically shutoff using a solenoid valve.

• Adjustable torque

• Group management

Group with various no of bolt quantity can be made.

• Keyboard operation

• Management of torque data

Various Error Detection

• Detection insufficient torque and over torque

• Detection of double tightening

• Detection friction out of tolerances

• Detection of damaged threads

• Detection of too long / too short bolt

• Detection of cross threaded threads

In yokota pneumatic system wrench torque is developed with an oil pulse chamber located between the motor and the main shaft. System wrench compresses the oil in its chamber to produce oil pressure which is transferred to the main shaft to generate rotation torque.

In yokota pneumatic system wrench torque is developed with an oil pulse chamber located between the motor and the main shaft. System wrench compresses the oil in its chamber to produce oil pressure which is transferred to the main shaft to generate rotation torque.

Yokota system wrench therefore have a vast reduction in the tightening reaction, noise and vibration in comparison with conventional impact wrenches which makes use of impact force to generate torque.

Yokota system wrench are categorised in different models: -

• YEX series

YEX series in yokota pneumatic system wrench is the most commercially used system wrench. It provides accurate tightening at a very high speed up to 9000 RPM with torque up to 570 NM.

Tightening achieved in YEX series is reaction less due to its oil – pulse unit chamber and the tightening accuracy of ±10%.

YEX series comes in pistol, straight and with handle model for various application.

• TKA series

TKA series were developed by the concept of “More Ecology” aiming at the reduction of energy cost and oil mist for the global environment in the future.

TKA series system wrenches have angle monitoring feature unlike its counterpart which have only torque control feature.

TKA series tools have extremely compact built in rotary encoder detects rotation angle and direction by 1 degree.

TKA series have a tool torque range of 20 ~ 160 Nm with speed up to 7000 RPM with tightening accuracy of ± 10%.

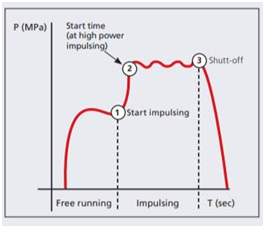

• Pokayoke controllers YTC-3

The system is controlled by measuring the air pressure at the inlet side of the air motor. This air pressure varies from free running to final tightening. By this measured air pressure, the controller detects contact of the bolt head (point 2). Upon contact, the adjustable timer gives the shut-off signal (point 3). Adjustability of the timer takes care of adoption to either hard or soft joints. Similar, the controller detects double hits and trigger release before shut-off.