Choosing an electric screwdriver to tighten up your assembly process

Kilews electric screwdrivers

High performance, Brushless, Screwdriver with high durability

- Number 1 selling Electric Screwdriver Brand in India

- Electric Screwdrivers with Brushless variant

- High speed models with two times the speed of Pneumatic screwdrivers

- Noise free and ergonomic operation

- OK/NG signals available and line integration can be done

- Error detection like cross thread, double hit etc. possible

- High Carbon Steel clutch is used for super durable life

- Available up to 50nm torque

- Torque display variant also available

Adventages of Brushless Motor

- • Clean room operation

- • Easy to Maintain

- • Durable, Long lifespan, Less Noise

- • Low motor heats

Brushless can achieve added value (Counter / Signal output / Special Applications)

1. Screw Counter

In operation, working errors (mechanical/human) can cause screws to be not fasten, over-fasten, or even incorrect numbers of fastening screws. To decrease the errors, Error prevention machine is needed to caution the user and confirm the number of screws

2. Automation equipment

Users to increase production efficiency must reply on automation equipment. When the screw driver applied for the automation equipment, it should support signal output / input to the automation equipment for the PLC interpretation.

3. Special Applications

Users will use the screwdriver in some special purposes, such as for some work piece, the user should divide the fastening process into 2 steps instead of fastening it directly. For the 1st step, the users fasten the screw to the half of the screw’s length. The 2nd step is to finish the fastening process.

COUNTER -

- Count display on Power Controller or on Screwdriver.

- Can be integrate with PLC with I/O of counter.

- Give OK/NG output to conveyor PLC for interlocking.

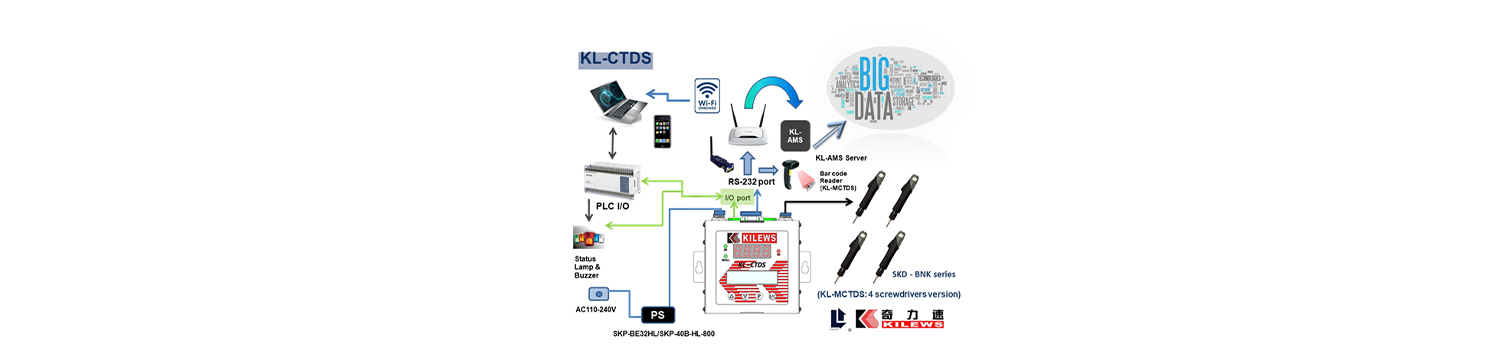

KL-CTDS: Torque display system -

KL-CTDS is able to display tightening torque, output tightening torque, and output tightening status. Also integrate with PLC & Conveyor for Interlocking.

Features -

1. Prevent errors:

Time / Torque / Thread

2. Counts:

Number of Screws

3. I/O signal :

OK / NG / OKALL / Input signal for Start up /Input signal for Reverse/ Input signal for brakes/ Input signal for confirmation

4. Data transmission:

- Production status monitoring

- Production Statistics

- Feasting data analysis

Display:

- 1. 4 digits and 7 steps torque value display

- 2. 16*2 LCM display settings