Choosing between Microntech YOKOTA Dynamic torque tester Vs Static torque tester

YOKOTA is one of the best manufacturers of assembly tool, the manufacturing headquarter is in Japan. Yokota introduced many types of assembly tools like pneumatic, electric, shutoff, non-shutoff and cordless ...etc. YOKOTA tool is best in the results and very effective at production line. YOKOTA developed a Dynamic and Static torque tester, which is used to measure the torque.

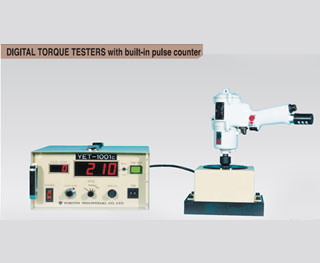

Static Torque tester –

Yokota Static torque tester, which is used to measure the torque value delivered by tool. There are many type of models developed by the YOKOTA according to the torque (5Nm o 1000Nm). This type of torque tester is used to measure impact, impulse, drivers, ratchet wrenches, torque wrenches and DC types of tool, but in DC tool there is a lot of vibration and jerk, and so to measure the higher torque there is a need of reaction arm, which is also use to hold the tool. Basically torque tester is consists of static transducer which measures the load developed on it. There is a box type structure which is having transducer and another side is torque display and control monitor. It is having large digital display, having high precision within R.O.±0.5% (static load and the main feature is that it measures the automatic pulse counter (counting blow number) is built in.

Dynamic Torque tester –

YOKOTA Dynamic torque testers are useful to dynamic fastening torque. It consists of one controller and torque transducer which can monitor the torque produce by tool during the tightening. There are five different models of Torque transducer developed by YOKOTA for torque range from 2.8Nm to 250 Nm. Dynamic torque measurement is possible with a built-in or a separate in-line torque transducer, in this case torque measuring is only possible where the tools have direct torque transmission. YOKTA Dynamic torque transducer used with impulse tool, hand torque wrench and ratchet wrenches etc. during their actual fastening work.

Choosing between YOKOTA Dynamic Vs Static torque tester –

Static torque tester used to measure the torque of tool because it can’t set with tool and measure the torque during tightening the application joint, this tester are used in maintenance are to test the torque value of tool after repairing and during checking time for condition of tool. Dynamic torque testers are used to measure the torque value of tool on joint, this tester is suitable to check the dynamic fastening torque because of it shape and size and YTT series dynamic torque tester are easy carry and move. So according to the uses you can select the YOKOTA torque testers.

Microntech is the leading assembly solution provider in India, which provides the best results to its customers in a sense of quality and accuracy with its services. Microntech has a presence everywhere in India and because of more than 30 years of experience is a preferred supplier for several manufacturers in India. To know more about assembly solutions provided by Microntech please visit our website www.microntechgroup.com otherwise you can contact your nearest Microntech branch by emailing at sales@microntechgroup.com to schedule a demo or a visit for any assembly related issues you are facing on your production line