What is a Master Controller in multi spindle tightening operation??

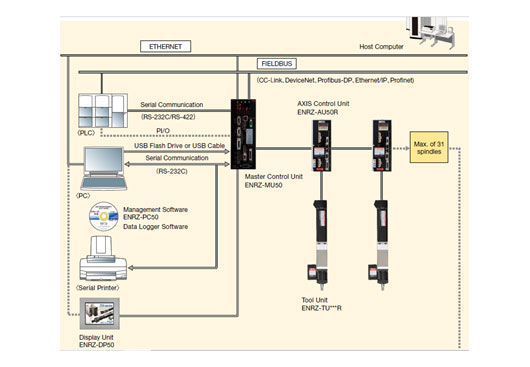

Estic fixture tools have two controllers; one is Axis controller & one is Master controller. Axis controller unit is must for every fixture tool but Master unit has its unique features that’s why somewhere it is mandatory to use . But this depends on the need of customer because axis control unit has also the enough features so master unit is only required where advanced features required or where Multi spindle tightening required So now we discuss the use of master controller in multispindle tightening:

• FOR SYNCHRONIZATION

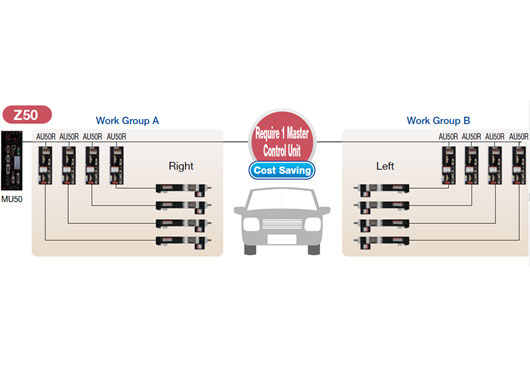

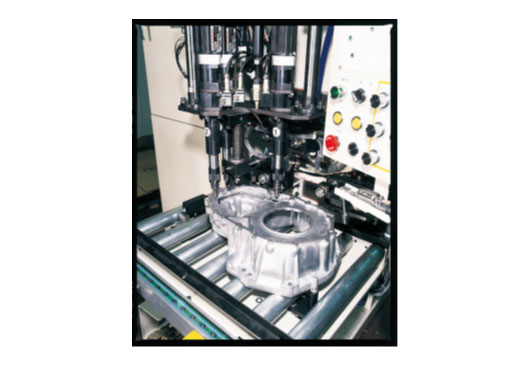

Many of the customers uses multi spindle fixtures like set of 4 spindle or 5 spindle , it depends on how many bolts they have in their application . In that case they also need synchronization the spindle with each other that means they want their work process in same manner , if one spindle is facing some trouble during fastening & if it shows NG then all the spindles will stop automatically on the same position where spindle one has stucked . This function is very important where application are very critical to tight & they have soft joint & they want to tight all the bolts on same time & in same speed & in same manner also . So this function prevent the application from damage . So this is only possible when you use Master Unit with axis unit. We can connect 31 spindles with one Master unit and trigger all the spindles at same time with the use of master unit .

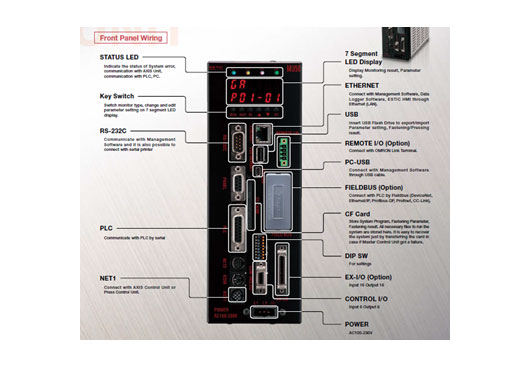

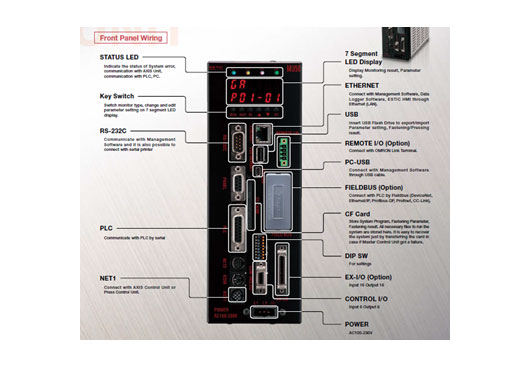

• FOR FIELDBUS COMMUNICATION/LAN AND USB ALSO

Axis unit only have one port for the communication that is Serial port ( RS232C) , if customer need LAN or USB then master unit is must to use . Also if data traceability through fieldbus communication is required like through CC link , Profibus , Profinet , Ethernet IP , Device Net etc then master unit is must to use .

• MORE INPUTS & WITH EXTEND & REMOTE I/O

Axis control unit has only 12inputs & 22 outputs , also we cannot do the sync wiring in input means in axis unit we can only give the plus in input common & also we cannot do the source wiring in output means we can only give the minus in output common , we cannot give plus in output common . So master unit has both the options sync as well as source in both input & output and master unit has 16 inputs & 16 outputs . They also have the option of Extend I/O & remote I/O.

• MORE TIGHTENING DATA

Axis Unit stores only 5115 tightening data & 50 system error data , they also do not store the torque curve history . On the other hand master unit stores 20000 records of tightening data , 200 system error data & 50 torque curve data .

• DATA THROUGH USB FLASH DRIVE

We can export and import the data in controller through USB Flash drive like fastening history file & Program parameter file . This feature is not available in Axis unit.

Microntech is partner of Estic Industrial Co. in India and represents them all over India with 15 offices in different cities. To know more about fastening and about Estic DC Nutrunner please log on to website www.microntechgroup.com or contact at sales@microntechgroup.com