Yokota Pneumatic System Wrench

Overview :

The controller can make judgment of torque OK or NOK

Features :

• Automatic stop

The controller is automatically stopped by a signal from the torque sensor built into the main shaft of the tool.

• High/Low air pressure switching

When using high /low air pressure switching function ,the controller rotates at low air pressure fist, then the display start torque is reached, the lower air pressure will switch to high air pressure for stable tightening .

• Set value change

8 different (work a through) parameter setting can be set Torque , group management setting and 4 tool connected .

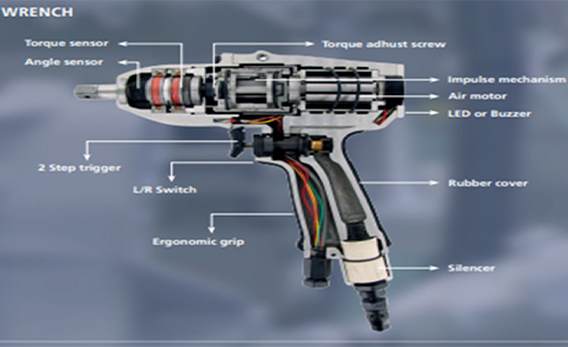

Configuration :

System wrench along with optional torque conlroller shows tightening torque values,total and remaining number of bolt/nuts at group administration on the digital display as well as fastening result such as “over NG”,”OK”,”lower NG” on the lamp indication which is reported by buzzer sound from the tool as well . with a printer connected ,the system print out group number ,torque value,judged result in comparison with the preset torque value so that torque management over the fastening work can be archived. Yokota System Wrenches are transducerized pulse tools, designed to meet two major demands of customer, i.e. high tightening speed and high accuracy. Yokota System Wrench has a built-in torque transducer and angle encoder on the main shaft which helps in detecting abnormalities like cross thread, double hit.

Yokota Pneumatic System Wrench :–

Yokota has developed pneumatic system wrench for the purpose of tightening bolts at a very high speed with accuracy. Yokota pneumatic system wrench has features like: - count bolts in a group, detection of tightening error like under & above tightening, double hit, cross thread, free bolt. Pneumatic system wrench can be integrated with production line control system for quality production & it also has an ability to exchange the tightening data for analyses & traceability purposes Pneumatic system wrench does not only have tools with having a torque transducer on the main shaft but also an angle encoder to monitor tightening angle. By controlling the torque and monitoring the angle, all errors that can occur during the tightening process are detected.

Features of Pneumatic system wrench: -

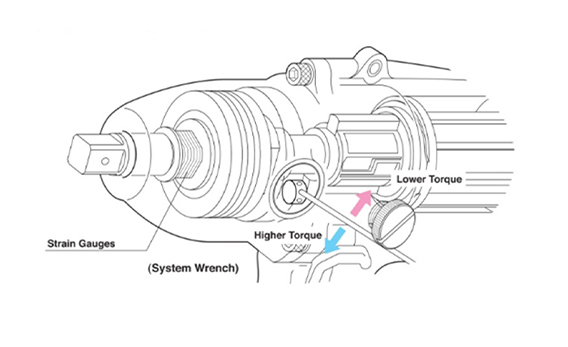

Torque is directly detected in yokota system wrench by the strain gauge sensor is attached to main shaft for precise tightening data can be obtained.

The tool can be automatically shutoff using a solenoid valve.

Group with various no of bolt quantity can be made.

High / Low –pressure switching

The selection of high or low air pressure. The will be enabled if two (SV1.SV2) Solenoid valves are installed.

If command Y8

1 - Only low pressure can be used.

2 - Starts with low pressure, and changes to high pressure if the display torque is in excess of the displayed start torque.

3 - Only high pressure is used.

The tool shuts off automatically at the preset torque value by means of optional solenoid valve.

Various Error Detection

Yokota system wrench are categorized in different models: -

1.YEX Series : - Yokota has developed pneumatic system wrench for the purpose of tightening bolts at a very high speed with accuracy. Yokota pneumatic system wrench has features like: - count bolts in a group, detection of tightening error like under & above tightening, double hit, cross thread, free bolt. Pneumatic system wrench can be integrated with production line control system for quality production & it also has an ability to exchange the tightening data for analyses & traceability purposes Pneumatic system wrench does not only have tools with having a torque transducer on the main shaft but also an angle encoder to monitor tightening angle. By controlling the torque and monitoring the angle, all errors that can occur during the tightening process are detected.

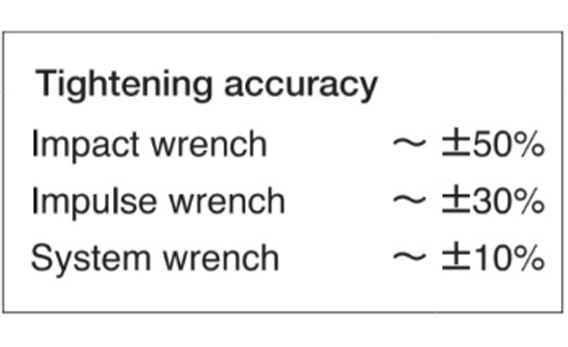

2.TKa Series : - TKA series were developed by the concept of “More Ecology” aiming at the reduction of energy cost and oil mist for the global environment in the future. TKA series system wrenches have angle monitoring feature unlike its counterpart which have only torque control feature. TKA series tools have extremely compact built in rotary encoder detects rotation angle and direction by 1 degree. TKA series have a tool torque range of 20 ~ 160 Nm with speed up to 7000 RPM with tightening accuracy of ± 10%.

3.Pokayoke controllers YTC-3 : - The system is controlled by measuring the air pressure at the inlet side of the air motor. This air pressure varies from free running to final tightening. By this measured air pressure, the controller detects contact of the bolt head (point 2). Upon contact, the adjustable timer gives the shut-off signal (point 3). Adjustability of the timer takes care of adoption to either hard or soft joints. Similar, the controller detects double hits and trigger release before shut-off.

Structure of system wrench : -

The transducers are fitted on the output drive of a power tool where it measures the torque applied by the tool to the fastener on a specific part of the product assembly. This measurement provides important information about how the joint is being tightened by the tool and can assist in establishing specifications for proper assembly. The rotary torque transducer can also measure the angle of fastener rotation which is also an important indication of the joint’s reliability.

Driving Part : -

System wrench with the strain gauge put on the main shaft of the impulse unit picks up the twisting torque generated on the main shaft while impacting and transforms it to the electric signal the signal is transacted by the fastening torque controller YETC. The digital display of tightening torque value total and remaining number of bolt is done as well as “over NG”,”OK”,”lower NG” on the lamp indication which is reported by buzzer sound from the tool as well . with a printer connected ,the system print out group number ,torque value, judged result in comparison with the preset torque value so that torque management over the fastening work can be archived.

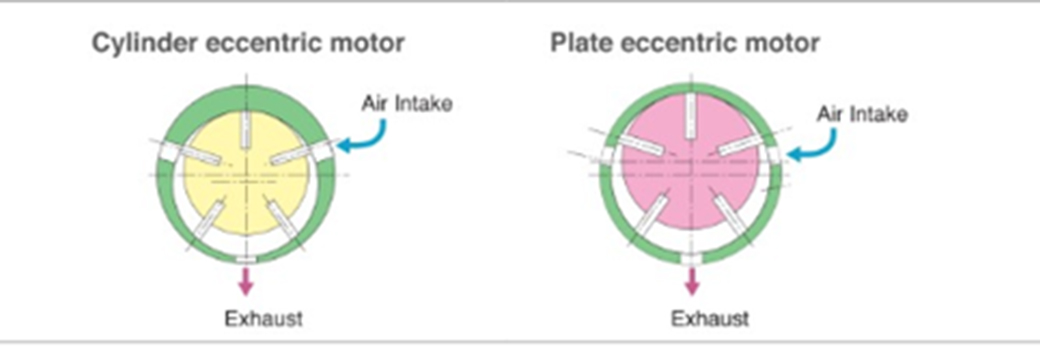

Motor work :-

In yokota pneumatic system wrench torque is developed with an oil pulse chamber located between the motor and the main shaft. System wrench compresses the oil in its chamber to produce oil pressure which is transferred to the main shaft to generate rotation torque.

Advantage : -

Tightening accuracy : -

Above accuracy is subject to working conditions and is not guaranteed value